Die cutting is a critical converting process used across numerous industries to create precise, uniform parts from a variety of materials. Among the various die cutting methods, steel rule die cutting stands out as a cost-effective, versatile choice. This process is employed in diverse applications, from packaging and consumer goods to automotive components and medical devices.

Understanding Steel Rule Die Cutting

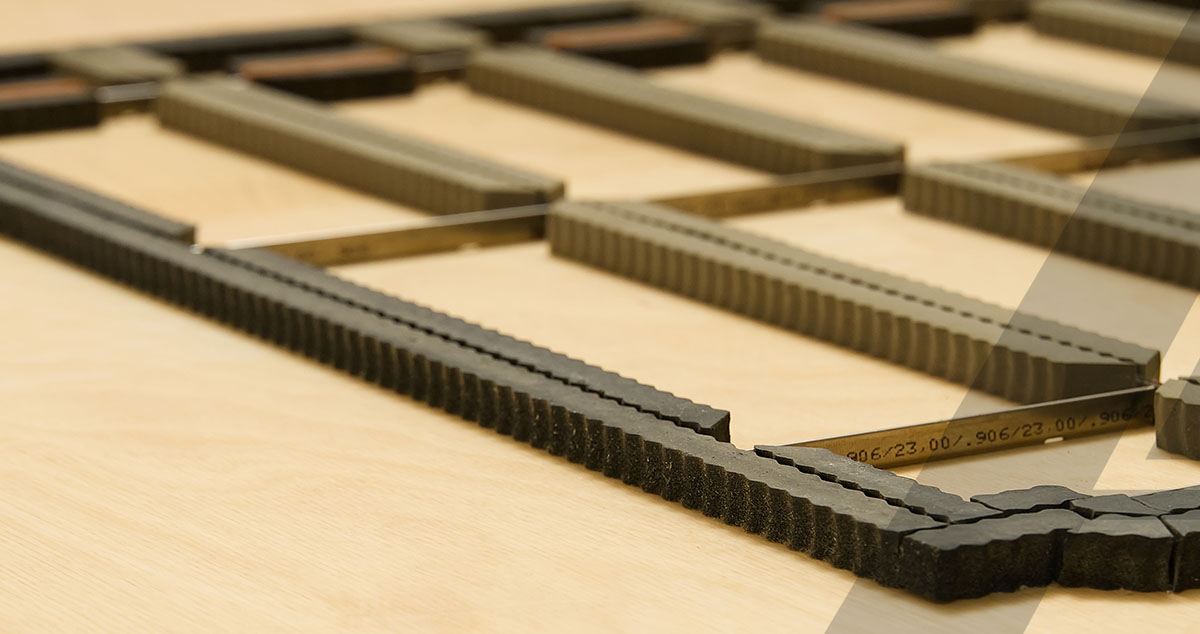

Steel rule die cutting involves using a sharp steel blade, known as a “steel rule” or “steel knife,” which is pushed into the material to cut out the desired shape. It is a two-dimensional cutting process, also called flatbed die cutting.

Steel rule die cutting can process numerous soft and semi-rigid materials since it can create clean cuts without warping or bending the material. Steel rule die cut materials include:

- Foam such as polyethylene or polyurethane

- Paper

- Foils

- Rubber, like neoprene and silicone

- Plastics such as polyvinyl chloride, polypropylene and polyester

- Tapes & Adhesives

The Steel Rule Die Making Process

A steel rule die consists of a steel rule, die board, ejection rubber and a cutting plate. The die board is the base material into which the steel rule is embedded. The ejection rubber is a foam or rubber material that helps eject the cut parts from the die, and the cutting plate serves as a cutting surface.

The steel rule die making process involves several key steps:

- Design and consultation: The process begins with a consultation to note specifications and requirements for the desired part.

- Die board preparation: The die board is cut to the required size, and the design is transferred onto the board using CAD software.

- Cutting the design: The shape is cut into the die board with a router cutter or water jet machine, creating a channel for the steel rule.

- Bending the steel rule: The steel rule is angled into the desired shape to fit precisely into the cut channel.

- Assembly: The bent steel rule is carefully fitted into the router-cut channel in the die board, and ejection rubber is added to help remove the cut parts from the die.

- Quality control: A full optical inspection is conducted to ensure accuracy and quality before the die is put into production.

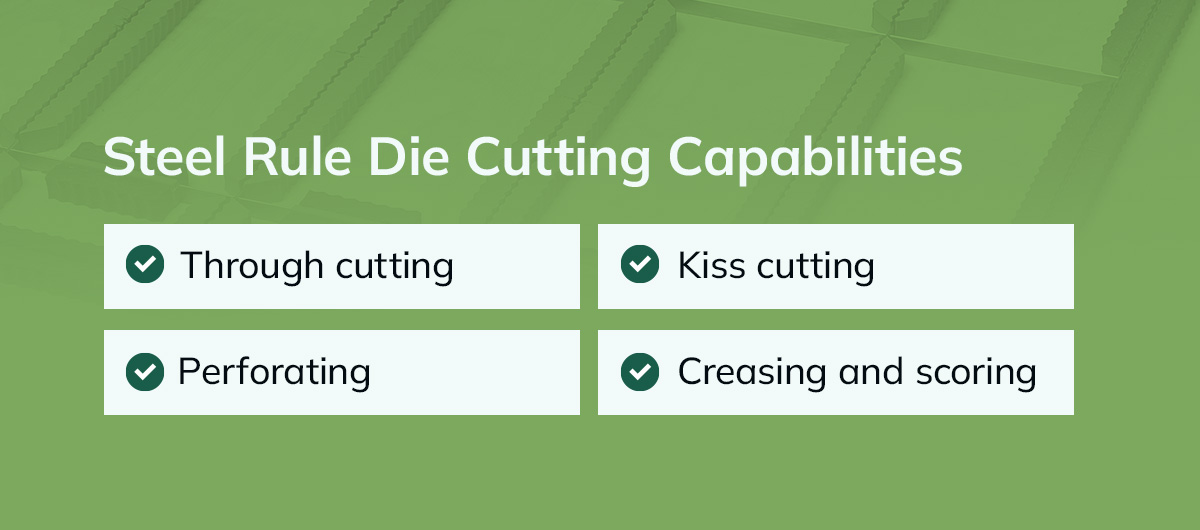

Steel Rule Die Cutting Capabilities

Steel rule dies offer various cutting capabilities that make them suitable for multiple applications. These capabilities include:

- Through cutting, where the die cuts completely through the entire material.

- Kiss cutting, which involves cutting through the top layers of the material while leaving the backing layer intact.

- Perforating, which creates a line of small holes for easy separation of the material.

- Creasing and scoring, which make an impression or partial cut in the material to facilitate folding.

Steel Rule Die Types

Steel rule dies come in various types designed for specific applications.

- Blanking Dies: Blanking dies are also known as shearing or stamping dies. They are used for cutting out simple shapes in a single step. These dies are ideal for producing large quantities of identical parts quickly and efficiently.

- Combination Dies: These incorporate multiple cutting operations, such as cutting, scoring and perforating, in a single die. This type of die is particularly useful when creating parts that require different cutting techniques, as it eliminates the need for separate dies and streamlines the production process.

- Progressive Dies: Progressive dies perform a series of cutting operations in sequence as the material is fed through the die. This die type is well-suited for producing complex parts that require multiple cutting steps, as it allows for precise alignment and consistent results.

- Progressive Feed Dies: These dies work similarly to progressive dies but with a continuous feed of material through the die. This type of die is optimal for high-volume production runs, as it minimizes material waste and reduces the need for manual handling between cutting steps.

Advantages of Steel Rule Die Cutting

The steel rule die cutting process offers several benefits over other cutting methods. Advantages of steel rule die cutting include:

- Customizability: Steel rule die cutting allows for high customization in creating unique shapes and designs. The steel rule can be bent into intricate patterns, enabling the production of parts with complex geometries and fine details.

- Flexibility: Steel rule die cutting can process many materials, including larger, thicker ones like foam, rubber and cardboard. This flexibility enables manufacturers to produce parts for various applications using a single cutting method.

- Sharpness and precision: Steel rule dies produce sharp, crisp cuts compared to some cutting methods. The steel rule’s sharpness ensures clean, precise edges on the cut parts, minimizing the need for additional finishing processes.

- Minimal deformation: If done professionally, steel rule die cutting causes minimal material deformation during the cutting process. The process helps maintain the integrity and dimensional accuracy of cut parts, which is particularly important when working with delicate or sensitive materials.

- Short runs and quick turnaround: Steel rule die cutting is ideal for small orders or short production runs. The relatively low setup costs and fast turnaround times make it viable for prototyping, development and long term production.

Applications of Steel Rule Die Cutting

Due to its numerous benefits, steel rule die cutting is used in various industries, including the following:

- Electronics: Steel rule die cutting is employed in the electronics industry to produce insulators, spacers, thermal interface materials, EMI or RFI shielding gaskets and conductive adhesive tapes.

- Medical: In the medical field, steel rule die cutting produces medical disposables, enclosures, brackets, adhesive pads, electrodes and intricate filters.

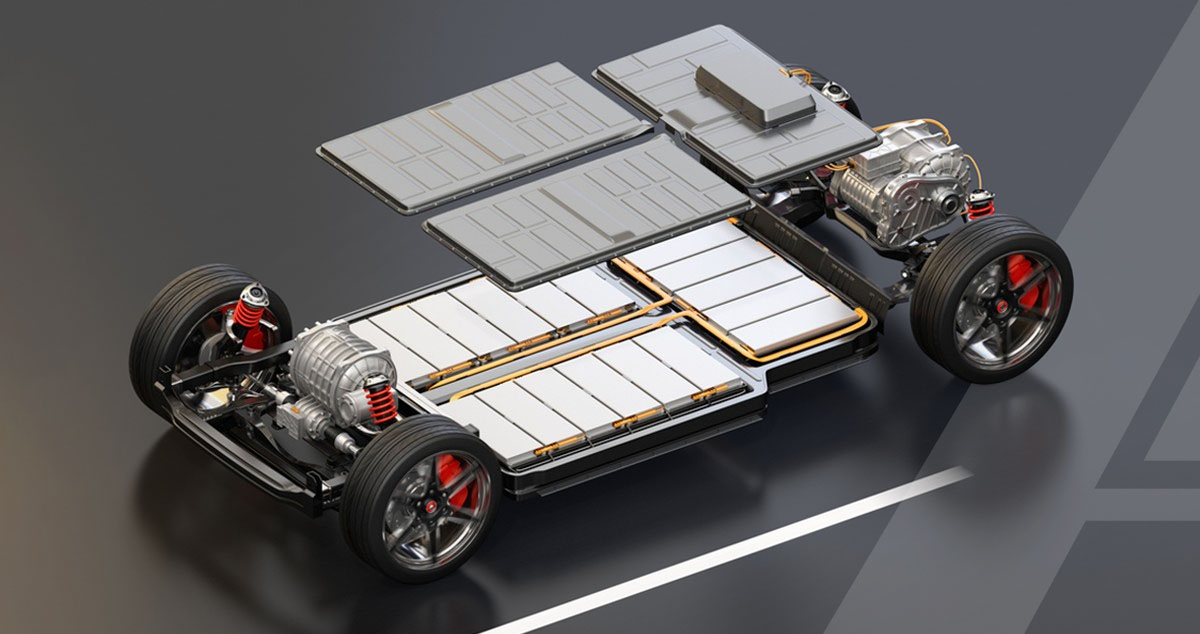

- Automotive: In the automotive sector, steel rule die cutting produces gaskets, seals, insulation, soundproofing components, interior trim parts and vibration-dampening pads.

- Packaging: Steel rule die cutting is widely used in the packaging industry to create boxes, cartons, blister packs, clamshell packaging, corrugated displays and foam inserts.

- Consumer goods: Steel rule die cutting is used to create toys, game pieces, arts and crafts supplies and promotional items. It’s also used to make household items like sponges and cleaning pads.

- Printing: The printing industry relies on steel rule die cutting for clean, accurate cuts for business cards, brochures, labels, stickers, postcards and other printed materials.

- Other applications: Steel rule die cutting also finds use in producing control panels, overlays, membrane switches, gaskets for appliances and machinery, and insulation for construction and HVAC systems.

Experience Advantage Converting’s Die Cutting Expertise

Advantage Converting is a leading provider of high-quality custom die cutting services. Our state-of-the-art equipment, experienced team and dedication to customer satisfaction enable us to produce precise, custom die cut components for various industries at a fair cost.

With ISO 13485 certification and as a 3M Preferred Converter, we demonstrate our commitment to quality and adherence to strict industry standards. Advantage Converting is your trusted partner for all your die cutting needs, from initial consultation and prototyping to full-scale production.

Contact us today to discuss your project requirements and experience Advantage Converting’s expertise, innovation and exceptional turnaround time, even for the most complex designs.