Rubber Materials

Rubbers

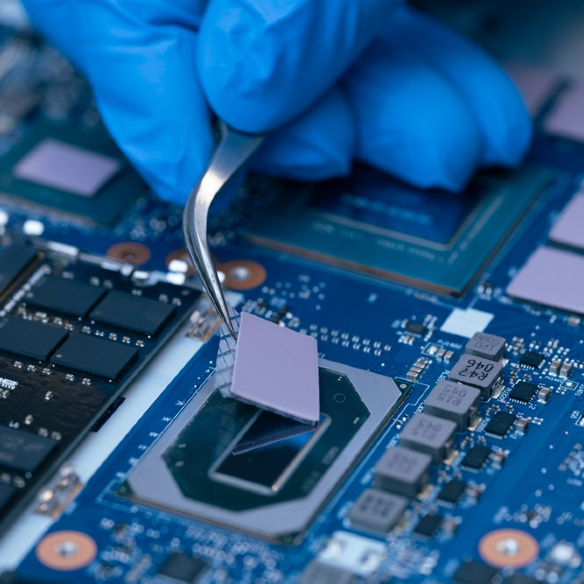

Foils are often used in the electronics industry to protect components from electromagnetic interference (EMI) and radio frequency interference (RFI). Foils can also provide acute resistance to corrosion and chemicals. Advantage Converting manufactures specialty EMI/RFI shielding using a variety of metal foils.

Foils are available as stainless steel, lead, aluminum, and copper, and can have conductive or non-conductive properties. Leveraging deep materials science expertise along with precision die-cutting, the experts at Advantage Converting can select and manufacture a foil that meets your unique application requirements.

See Our Work

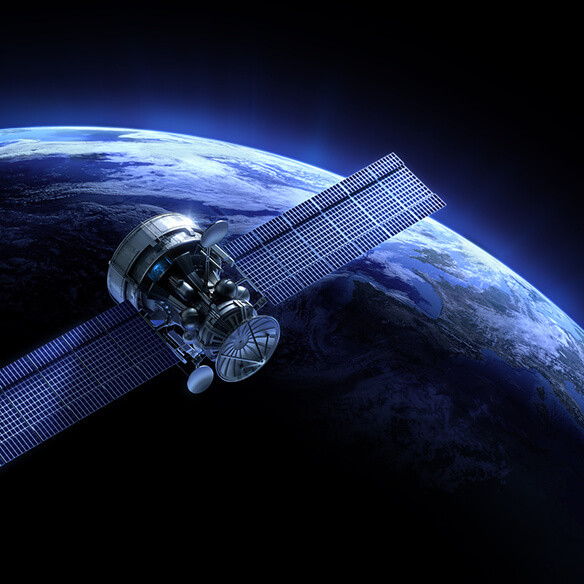

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: When do I need a clean room?

Clean room manufacturing is primarily used when manufacturing sensitive materials that can be easily contaminated or affected by particles in the air. For example, at Advantage Converting, we have used our clean rooms to manufacture advanced wound care products, solar panel components, and vibration dampeners for the aerospace industry. However, a clean room can be used for any converted good. Our experts can work with you to determine clean room requirements for your project.

Q: What manufacturing processes does Advantage Converting perform in their clean rooms?

We can perform any manufacturing process in our clean rooms, including custom die cutting, laminating, slitting and rewinding, and roll-to-roll manufacturing.

Q: What is clean room manufacturing?

Clean room manufacturing is the use of an enclosed area with strict environmental controls to manufacture sensitive components. The controlled environment – or clean room – limits the presence of dust, airborne microbes, aerosol, and chemical vapors to prevent environmental contamination of sensitive components, such as those for medical, electronic, and aerospace applications.

Advantage Converting has multiple clean rooms that are available for all converted goods. Our clean rooms are certified as ISO 8 / Class 100,000 and ISO 7 / Class 10,000.