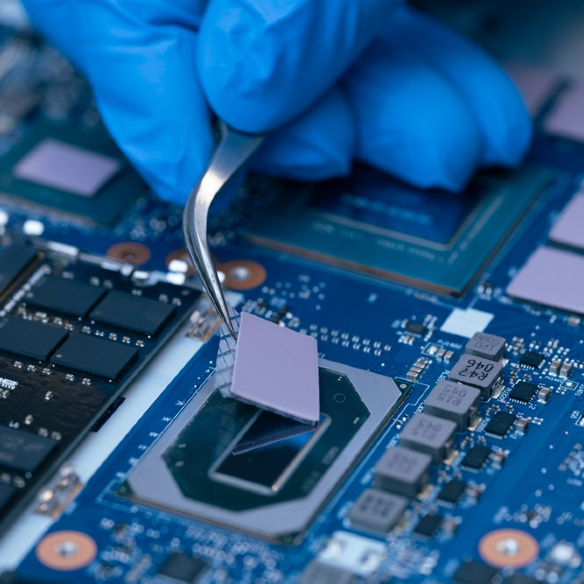

Thermal Management Material

Heat Transfer Capabilities

All industries are currently trending toward smaller and denser, yet more powerful products. As a leader in thermal management, Advantage Converting has the manufacturing expertise to convert efficient heat-transfer solutions to protect sensitive components.

If not properly managed, the heat generated by an electric current can cause a device to malfunction. Thermal interface materials transfer heat to keep devices within safe operational temperatures. Advantage Converting uses a variety of lightweight thermally conductive adhesives, gap fillers, and heat spreaders. We also use pressure-sensitive tapes, silicone sponge materials, and thermal fabrics to dissipate heat.

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: When do I need a clean room?

Clean room manufacturing is primarily used when manufacturing sensitive materials that can be easily contaminated or affected by particles in the air. For example, at Advantage Converting, we have used our clean rooms to manufacture advanced wound care products, solar panel components, and vibration dampeners for the aerospace industry. However, a clean room can be used for any converted good. Our experts can work with you to determine clean room requirements for your project.

Q: What manufacturing processes does Advantage Converting perform in their clean rooms?

We can perform any manufacturing process in our clean rooms, including custom die cutting, laminating, slitting and rewinding, and roll-to-roll manufacturing.

Q: What is clean room manufacturing?

Clean room manufacturing is the use of an enclosed area with strict environmental controls to manufacture sensitive components. The controlled environment – or clean room – limits the presence of dust, airborne microbes, aerosol, and chemical vapors to prevent environmental contamination of sensitive components, such as those for medical, electronic, and aerospace applications.

Advantage Converting has multiple clean rooms that are available for all converted goods. Our clean rooms are certified as ISO 8 / Class 100,000 and ISO 7 / Class 10,000.