Electronics Converting

Converting Services for Electronics

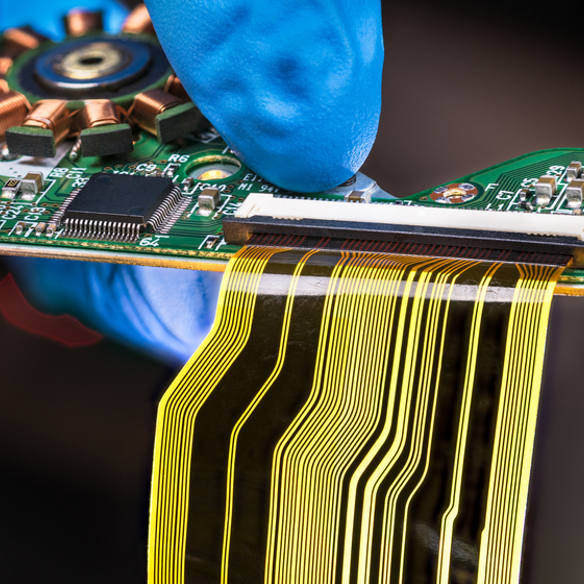

Advantage Converting helps electronics manufacturers tackle their toughest converting challenges as they race toward smaller, more efficient devices. We combine our materials and applications expertise with proven conversion capabilities to provide high-quality services and solutions. Conversion services for the electronics industry include rotary and punch-press die cutting, specialty lamination, and precision slitting for thermal management, electrical insulation, carrier films, and printed circuit boards

Manufacturing Solutions for the Electronics Industry

At Advantage Converting, we’re committed to meeting each project’s unique needs from the early consultation stages to product delivery. We pride ourselves on exceptional customer service, superior product quality and the fastest turnaround times.

Examples of our manufacturing capabilities in the electronics industry include the following:

- Batteries: Advantage Converting has years of experience manufacturing and assembling battery components for electronic applications including solutions for products like electric vehicles and cellphones.

- Bonding and joining: We can help you choose the optimal bonding and joining material based on your product’s surface texture, size, shape and required adhesion strength.

- Electrical insulation: We manufacture electrical insulation from various materials that help protect sensitive components from chemicals, radiation, extreme temperatures and more.

- EMI and RFI shielding: Advantage Converting fabricates electromagnetic interference (EMI) and radio frequency interference (RFI) shielding materials to protect and preserve the life spans of electronic and digital components.

- Gasket and sealing: We offer various gasket and sealing capabilities to prevent leakage, hold pressure and block contamination where two electronic components interface.

- Surface protection: We manufacture a comprehensive range of surface protection solutions for electronic products, from phones and tablets to hand-held gaming systems and electric medical devices.

- Vibration dampening: Our vibration-dampening solutions protect sensitive electronic components from potentially harmful noise, shock and vibration.

Electronics Converting Services

Our extensive range of converting services enables us to solve the most complex challenges for electronic applications based on each client’s specific needs. We provide a range of manufacturing capabilities, including:

- Laminating: We offer various adhesive and nonadhesive lamination solutions to improve component stability, strength and durability, from producing individually laminated parts to offering laminated rolls up to 76 inches wide.

- Die cutting: Our state-of-the-art equipment, superior material selection and years of manufacturing experience allow us to offer one of the industry’s most diverse ranges of die cutting capabilities, including the ability to provide custom dies for any product.

- Clean room manufacturing: We provide clean room manufacturing services for the most sensitive electronic applications, including several climate-controlled clean rooms certified to ISO Class 7 and ISO Class 8 standards.

- Slitting and rewinding: As a recognized leader in precision slitting of pressure-sensitive and non-pressure-sensitive products, we utilize advanced slitting and rewinding equipment to solve the most complex manufacturing challenges.

Materials for Electronic Component Manufacturing

We leverage our partnerships with some of the industry’s most recognized material manufacturers to offer the most practical and effective solutions for your unique applications. Our ISO 13485 certification and 3M Preferred Converter status are just a few examples of our commitment to product quality and material expertise.

Types of materials we work with include:

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: When do I need a clean room?

Clean room manufacturing is primarily used when manufacturing sensitive materials that can be easily contaminated or affected by particles in the air. For example, at Advantage Converting, we have used our clean rooms to manufacture advanced wound care products, solar panel components, and vibration dampeners for the aerospace industry. However, a clean room can be used for any converted good. Our experts can work with you to determine clean room requirements for your project.

Q: What manufacturing processes does Advantage Converting perform in their clean rooms?

We can perform any manufacturing process in our clean rooms, including custom die cutting, laminating, slitting and rewinding, and roll-to-roll manufacturing.

Q: What is clean room manufacturing?

Clean room manufacturing is the use of an enclosed area with strict environmental controls to manufacture sensitive components. The controlled environment – or clean room – limits the presence of dust, airborne microbes, aerosol, and chemical vapors to prevent environmental contamination of sensitive components, such as those for medical, electronic, and aerospace applications.

Advantage Converting has multiple clean rooms that are available for all converted goods. Our clean rooms are certified as ISO 8 / Class 100,000 and ISO 7 / Class 10,000.