Case Study

Advantage Converting Meets Stringent Quality Control Requirements, Enabling Manufacturer to Expand Business

Challenge

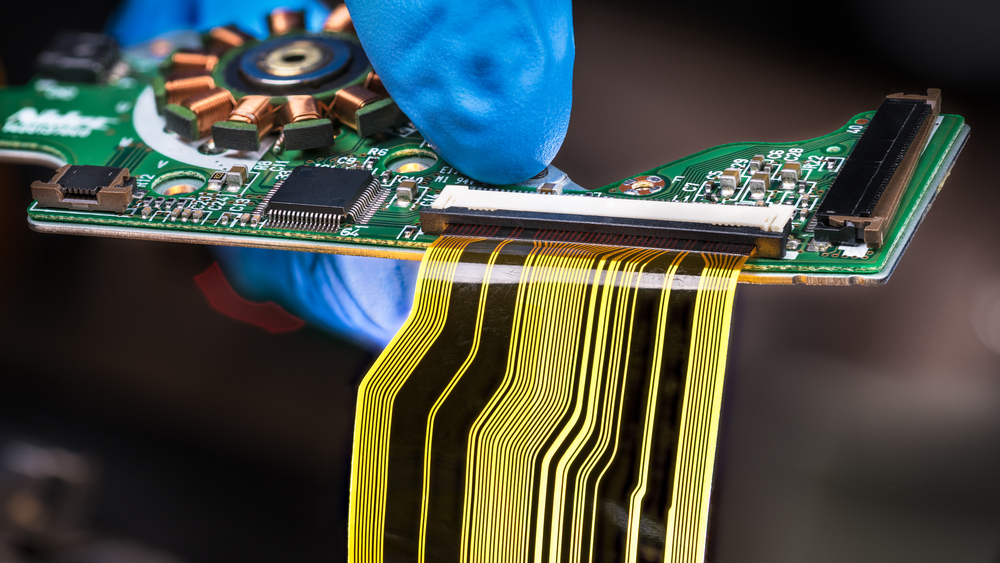

A major manufacturer of electronic components produces a multi-conductor ribbon cable that is used in various aerospace and electronic applications. The cable must be slit to various widths, each with a specific number of conductors. Because of the very sensitive nature of the cable, strict and manageable tension control is required during processing. The manufacturer tried to slit the cable in a lab, but this approach was unscalable. The company also needed a quality control process to verify the integrity of the cable after slitting.

Solution

The manufacturer approached Advantage Converting to provide slitting services and quality control. We developed tooling and a process to split the very sensitive cable while removing all voids in the fragile insulation on the wire. This involved the use of spark testing equipment to find and remove voids in the insulation wall. Advantage Converting also designed and produced custom reels on which to wind the cable after slitting. The reels ensure that the pliable cables maintain their integrity.

Results

- Advantage Converting’s scalability has enabled the manufacturer to expand its business into new use cases for the multi-conductor ribbon cable

- The quality control process provides assurance that the product consistently meets all requirements, enabling the manufacturer to maintain output

- The long standing, trusted partnership with Advantage Converting brings peace of mind