Thermal Management

Thermal Management Applications

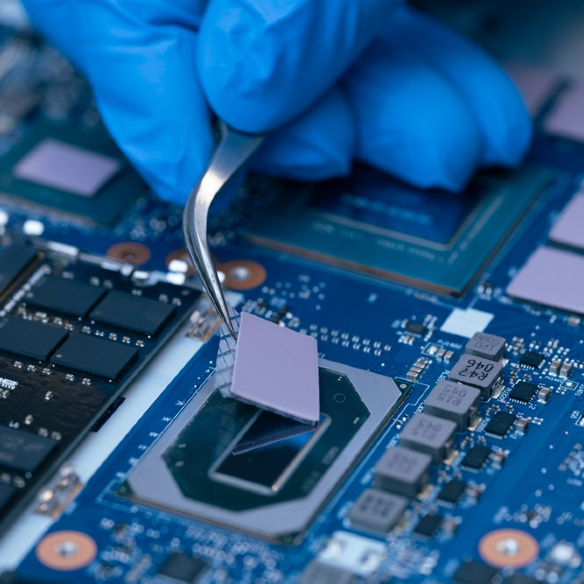

If not addressed appropriately, electric currents can generate heat that can affect a device’s reliability, life span and overall performance. Effective thermal management materials solve these problems by transferring or dissipating this excess heat to protect sensitive electronics and maintain safe operating temperatures. These solutions integrate seamlessly with products to create efficient pathways for heat dissipation while meeting strict space and weight requirements.

Advantage Converting’s thermal management expertise spans from basic components to complete system designs. Our engineers develop conversion processes based on a device’s specific thermal conductivity requirements, space constraints and operating conditions. Using advanced equipment, premium-grade materials and certified processes, we manufacture thermal management components that deliver reliable performance in the most demanding applications.

Custom Thermal Management Solutions

At Advantage Converting, our superior industry knowledge and decades of manufacturing expertise allow us to develop solutions for a range of applications. Several examples of our thermal management solutions include:

- Thermally conductive adhesives: These specialized adhesives create permanent bonds with materials while providing direct thermal transfer between components and eliminating air gaps that inhibit heat dissipation.

- Gap fillers: Gap fillers are conformable materials that compress to fill spaces between components, creating consistent thermal contact and efficient heat transfer across uneven surfaces.

- Heat spreaders: Heat spreaders are thin, highly conductive materials that can quickly distribute heat across larger surfaces to reduce hot spots and improve overall thermal efficiency.

- Pressure-sensitive tapes: Double-sided thermal tapes combine adhesive bonding, thermal conductivity and easy assembly while maintaining effective heat transfer.

- Silicone sponge materials: Compressible silicone materials offer both thermal management and environmental sealing to protect components while transferring heat.

- Thermal fabrics: Thermal fabrics combine flexibility with thermal conductivity, ideal for applications requiring conformable heat dissipation solutions.

Thermal Management Converting Services

Advantage Converting’s team works closely with customers to create innovative solutions for nearly any manufacturing application. Our ISO-certified facility, state-of-the-art equipment and experienced engineers help ensure consistent quality across all thermal management components.

Our converting services ensure precise, reliable solutions for your heat dissipation needs:

Laminating

Advanced laminating processes bond multiple layers of thermal and structural materials to produce composite solutions that combine heat dissipation with mechanical support.

Slitting and Rewinding

Our slitting and rewinding capabilities can convert large rolls or sheets into specific sizes that can quickly integrate into your production process.

Die Cutting

Custom slitting and rewinding converts wide rolls of thermal materials into specific widths while maintaining material properties and dimensional accuracy.

Clean Room Manufacturing

Our ISO-certified clean rooms accommodate thermal management components in controlled environments, ensuring contamination-free products for sensitive applications.

Types of Thermal Management Materials We Use

As a 3M Preferred Converter, we have direct access to the latest thermal management materials and advanced adhesive technologies. Our material selection process considers thermal conductivity, dimensional requirements and environmental conditions for optimal performance in your specific application. Examples of the materials we work with include:

Discover More About Thermal Component Converting Today

With decades of experience as a thermal converter, Advantage Converting brings unmatched expertise to your manufacturing challenges. Our engineers are excited to evaluate your thermal requirements and develop custom solutions that enhance product performance and reliability. Contact us today to discuss your project needs, or schedule a consultation with a thermal management specialist.