Die-cutting is a manufacturing process used to produce custom-shaped parts from sheet materials. The process involves using specialized machines fitted with sharp steel blades, called dies, to shear through the material. Class A die-cutting is a high-precision variant of this process designed to produce components with extremely tight tolerances.

In industries that demand the utmost accuracy and consistency, such as aerospace, medical devices and electronics, Class A die-cutting is often the preferred method for producing critical components and parts for end-use applications.

The Basics of Class A Die-Cutting

Class A die-cutting, or match metal die cutting, utilizes a set of male and female dies that fit precisely together, similar to a punch and die. When the dies close upon the material, they cleanly shear it into the desired shape with minimal compression or distortion of the surrounding area. This method can hold tolerances within + or – 10/1000 inches, significantly tighter than traditional steel rule dies.

The class A die-cutting process is suitable for a variety of materials, although it is most commonly used with thin, rigid substrates such as:

- Metal foils like aluminum, copper and stainless steel

- Plastics like polyester, polycarbonate and acrylic

- Composite materials such as carbon fiber

- Adhesive-backed materials like foams, tapes and gaskets

- Specialty materials such as Teflon, Kapton and Mylar

- Laminates and multi-layer constructions

Typical maximum thickness for class A dies is around 0.040-0.050 inches. As material thickness increases, it becomes more challenging to maintain the level of precision that defines class A die-cutting. However, skilled die makers can sometimes work around these limitations using special construction techniques and tool steels.

The Class A Die Cutting Process

The class A die-cutting workflow is a meticulous process that begins long before the dies ever touch the material:

- Consultation: The die cutting partner reviews the part design, material type, tolerances and special needs to determine feasibility and optimal manufacturing approach.

- Material testing: Samples of the chosen material are subjected to rigorous testing to ensure compatibility with the die-cutting process. Factors like hardness, tensile strength and shear resistance are evaluated to determine optimal cutting parameters.

- Die design: Specialized computer-aided design software designs male and female dies. Design is a critical step, as the precision of the final parts will depend entirely on the accuracy of the die geometry.

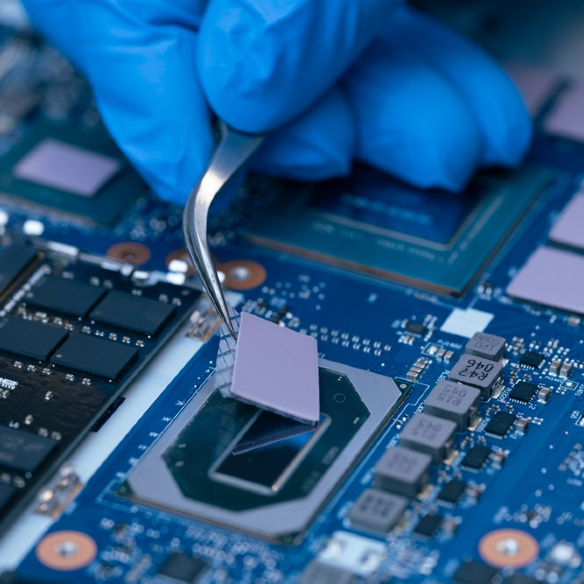

- Die manufacturing: The dies are machined from high-quality tool steel using state-of-the-art computer numerical control (CNC) equipment. They are then heat-treated to improve hardness and wear resistance, then polished to a mirror finish to ensure clean, precise cutting.

- Die mounting: The finished dies are loaded into the cutting press and carefully aligned to ensure perfect registration between the male and female components. The material is fed through the press automatically, usually from a continuous roll or sheet.

- Cutting: The press cycles rapidly, with the dies shearing cleanly through the material to produce the final parts. Depending on the complexity of the design, multiple cutting or forming operations may be performed in a single cycle.

- Inspection: Thorough inspections are performed on the finished components to verify that all specifications have been met. Ongoing quality control measures are employed throughout the production run to maintain consistency.

Advantages and Disadvantages of Class A Die Cutting

Class A die cutting offers several key benefits that make it an attractive choice for demanding applications:

- Precision: With tolerances as tight as + or – 0.001 inches, class A dies can produce parts with crisp, clean edges and unparalleled dimensional accuracy. Precision is critical for applications where slight deviations can compromise performance or safety.

- Speed: Once dies are manufactured and the process is dialed in, class A die-cutting can offer impressive production speeds. The dies are extremely durable and can withstand millions of cycles without degrading, allowing for high-volume production runs. Multiple parts can be produced with each press cycle, boosting throughput in many cases.

- Complexity: Class A dies can incorporate multiple cutting and forming operations into a single tool, producing complex parts in a single step. By consolidating operations, class A die-cutting can simplify production, reducing costs compared to multi-stage processes.

- Repeatability: Class A die-cutting offers exceptional repeatability because the dies are machined to such precise tolerances. Every part produced will be identical, with no variation in dimensions or edge quality. Consistency is essential for applications where interchangeability and reliability are critical.

Despite its many advantages, class A die-cutting has some limitations that must be considered:

- Designing and manufacturing the dies is a significant investment, often requiring specialized software, skilled labor and high-end CNC equipment.

- The lead time needed to produce class A dies is often longer than other methods.

- Very thick or abrasive materials can be challenging to cut cleanly and may cause excessive wear on the dies.

- Once the dies are manufactured, making changes to the part geometry can be difficult and expensive.

Class A Die Cutting Applications

The precision and reliability of class A die-cutting make it invaluable for numerous applications across diverse industries:

- Automotive: Class A dies produce critical components like gaskets, insulators and engine seals.

- Medical devices: Class A die-cutting is used in the medical industry to create parts like surgical blades, biopsy punches and diagnostic test strips that demand absolute precision and consistency.

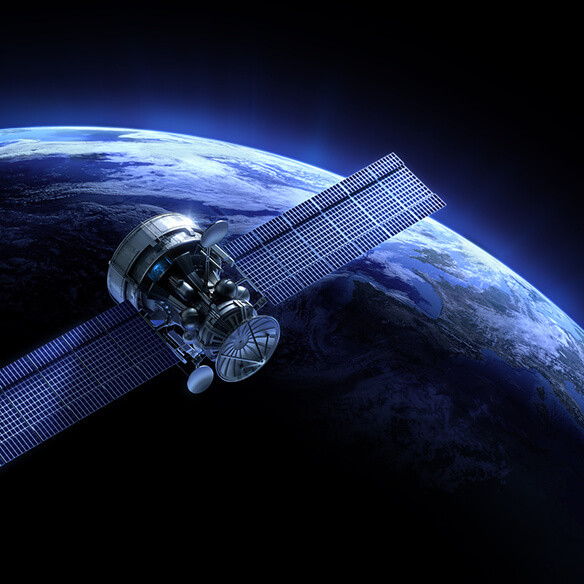

- Aerospace: The aerospace industry utilizes class A dies for elements like thermal insulation, EMI shielding and vibration-damping materials.

- Electronics: Applications in the electronics sector include circuit boards, touchscreen components and conductive films.

- Industrial: Class A die-cutting creates specialized parts like filtration screens, wear pads and fluidic manifolds for equipment and machinery.

- Retail and finance: Class A dies produce security-critical items like smart card inlays, RFID antennas and anti-counterfeit labels.

Class A Die Cutting vs. Other Cutting Methods

While class A die-cutting excels in precision, other methods offer their own advantages that may be better suited for certain applications.

Class A vs. Rotary Die-Cutting

Rotary die-cutting uses cylindrical dies to cut material from a continuous roll. It can operate at high speeds, producing thousands of parts per minute, making it ideal for high-volume, lower-precision applications. Rotary dies typically hold tolerances around + or – 0.010 inches, which is sufficient for many products. However, class A die-cutting offers better precision.

Class A vs. Flatbed Die-Cutting

Flatbed die-cutting, which uses steel rule dies, boasts faster setup times and lower tooling costs than class A die-cutting. It is an excellent option for shorter production runs and simpler part geometries. Flatbed dies can hold tolerances around + or – 0.025 inches, making them suitable for diverse applications. However, class A die-cutting still offers higher precision than flatbed die-cutting.

Class A vs. Laser Cutting

Laser cutting uses a focused laser beam to vaporize material, allowing the cutting path to be changed easily without the need for physical tooling. However, the heat generated by the laser can thermally stress the materials, leaving a heat-affected zone that may have altered properties or inferior edge quality. Class A die-cutting, on the other hand, produces clean, precise cuts without any thermal damage to the material.

Partner With Advantage Converting for Precision Die-Cutting

At Advantage Converting, we specialize in providing custom high-volume die-cutting services with a focus on quality, efficiency and customer success. Our state-of-the-art facility is ISO 13485 certified and staffed by industry veterans with decades of experience in precision manufacturing.

We have a proven track record of delivering innovative solutions for the medical, electronics, aerospace and specialty industrial markets. Our technical expertise and 3M Preferred Converter status allows us to be committed to continuous improvement allowing us to tackle even the most challenging projects with confidence. With industry-leading turnaround times and competitive pricing, Advantage Converting is your partner for success.

Contact us today to discuss your project and learn how we can help you achieve your goals.