The Future of EV Battery Assembly With Adhesives

In recent years, the United States has experienced a surge in demand for electric vehicles (EVs), driven by increasing environmental consciousness among consumers and government incentives. In the wake of this demand, which is likely to increase, many manufacturers seek ways to make these vehicles more efficient and easy to operate. Their strategies extend down to the smallest components of each car, including the bonders used in the batteries.

Adhesives have emerged as a premier solution for engineers seeking lightweight materials for EVs. Their continued consumer adoption depends on designing efficient and durable battery packs with maximum range, and adhesives are a crucial component in their design and assembly.

The Evolution of EV Battery Assembly

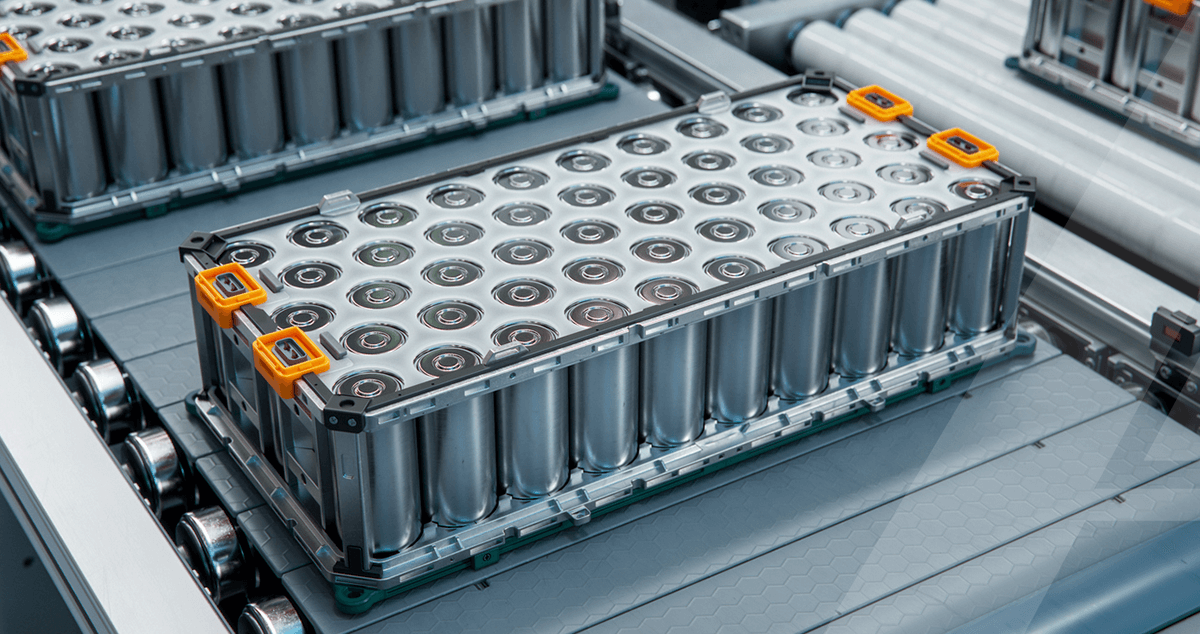

The automotive industry has seen many revolutions, and battery technology is at the heart of these vehicles. EV battery assembling is a complex process that requires stringent performance, temperature and safety requirements.

William Morrison introduced the first electric wagon to consumers between 1890 and 1891, and it became popular among urban residents by 1899. In the late 19th century, EVs were predominantly powered by lead-acid batteries, which relied on a chemical reaction between sulfuric acid and positive and negative plates to create energy. While these batteries were pioneers, they faced limited energy density and range.

Thomas Edison developed the nickel-ion battery in the early 20th century, which was a definite step forward in terms of assembly and usability. However, it didn’t become commonplace in EV applications. Enter the lithium-ion battery, which changed the game for EVs. Although they still require stringent assembly processes, welding and mechanical fasteners, the associated challenges are no longer an issue. A shift toward adhesives in battery assembly eliminates the need for mechanical fasteners, reducing battery weight and simplifying joining processes.

The Role of Adhesives in Modern EV Battery Assembly

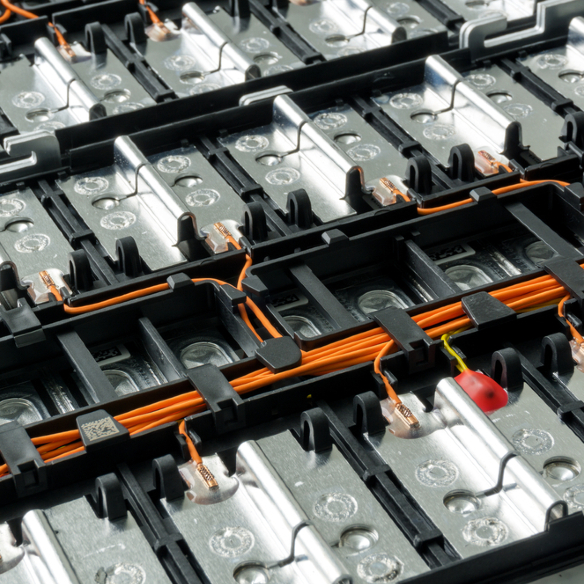

There are various use cases for adhesives in EV manufacturing, and they’re rapidly replacing mechanical fasteners and other joining technologies. Unlike traditional fasteners, their benefits extend beyond bonding. In addition to thermal management in EV batteries, they have many applications in battery assembly, including:

- Thermally conductive adhesives: These adhesives form part of the battery’s thermal management system, creating efficient thermal connections between components. They’re used at various locations in battery modules, including between individual cells and between cells and cooling plates.

- Gaskets and seals: Sealing EV batteries is essential to withstand environmental factors like humidity. Adhesives help create tight seals that safeguard the battery against moisture, debris and contaminants.

- Structural adhesives: EV batteries require bonds that can withstand a range of environmental stresses. Adhesives provide tensile strength to protect against impacts, vibrations and loads, with various levels of strength and flexibility depending on their location within the battery.

Adhesives are used at different locations within the battery module, including shell casings, cooling plates, small components, housings and enclosures. They dissipate heat, insulate electrical components and create strong structural bonds in all EV applications.

The Benefits of Adhesives in EVs

The use of adhesives in EV batteries is a rapidly growing area. They play a fundamental role in the design and manufacturing of these batteries due to their multiple benefits, which include:

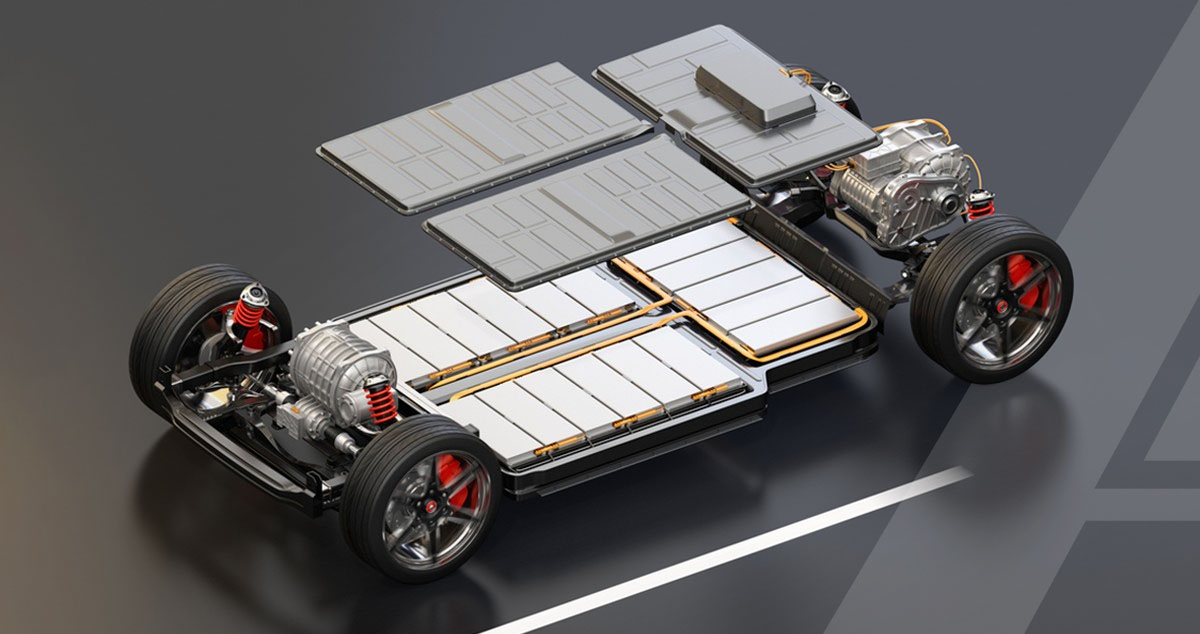

- Lighter and more compact design: One of the primary challenges in EV vehicle design is the battery weight. Traditionally, these batteries were heavy. The mechanical fasteners used in their assembly create possible points of concentrated stress that lead to fatigue failure and other issues. Adhesives bond the battery components securely without the need for mechanical fasteners. Adhesives can reduce battery weight while improving structural integrity.

- Thermal and electrical management: Adhesives create a more integrated design, which increases the battery’s energy density. Adhesion to battery substrates also fills the spaces between cells within and between battery modules. They promote better heat dissipation to ensure consistent performance and an extended battery life span.

- Enhanced performance: Adhesives optimize the thermal interface between battery cells and cooling systems, leading to extended range, faster charging and improved overall performance.

- Structural integrity and design flexibility: The use of adhesives in EV batteries reduces the risk of damage or failure, improving overall structural integrity. They bond various materials, including composites and metals, providing a nondestructive joining that preserves substance integrity and allows for more innovative battery designs.

Tapes and Adhesives in EV Battery Assembly

Safety is always an overarching concern in the automotive manufacturing industry. Lithium-ion batteries can present flammability concerns and endanger drivers. In addition, current battery manufacturing innovations center around increasing range, reducing charging times and cutting costs.

Tapes designed for EV batteries can address many of these challenges. They provide protection against thermal runaway, helping manufacturers and engineers maintain compliance. They also support the thermal interface materials that facilitate heat transfer between battery components. They’re used for cell-to-cell bonding, compression pads, gaskets and insulation. Using bonding materials from a company with 3M Preferred Converter status is essential for ensuring high-quality, effective adhesion. A 3M Preferred Converter company has the expertise to provide reliable adhesives for safety-critical applications.

From a manufacturing standpoint, tapes and adhesives streamline operations and improve efficiency, offering fast and simple bonding with improved structural integrity. They eliminate curing time and provide instant strength that positions them as an assembly aid in addition to a bonding alternative.

Challenges and Considerations in Using Adhesives for EV Battery Assembly

While adhesives offer many significant advantages to EV battery design and manufacturing, there are still challenges for widespread adoption. EVs generate considerable heat, which raises temperatures inside the battery enclosure. These adhesives and tapes must also withstand significant environmental exposure and be compatible with a range of materials, which has cost implications.

However, adhesive and sealant manufacturers are constantly developing new formulations that can better withstand high temperatures and exposure to harsh environments. The market is growing rapidly, which leads to an increased demand for advanced adhesives that can improve the efficiency, safety and reliability of EVs. There’s also a growing need for lightweight materials. Adhesives make their incorporation possible by providing durable, strong bonds that can withstand the inherent stresses of automotive applications.

The Future of Adhesives in EV Manufacturing

The role of adhesives in automotive manufacturing is likely to grow as the demand for EVs rises. An investment in thorough research and development of these technologies is expected as manufacturers develop new models and expand their production capacity. Adhesives will likely become more durable and reliable as adhesive and sealant technology advances.

Embrace the Future With Advantage Converting

When you’re manufacturing EV batteries or any other EV components, relying on adhesives is crucial. When you know you have the highest quality bonding materials at your disposal, you can focus on innovation. Using adhesives in EV battery assembly offers many advantages, including quick turnaround times and superior quality.

At Advantage Converting, we have over 40 years of experience in manufacturing adhesives and other components for a range of industries. As a 3M Preferred Converter, our manufacturing capabilities maximize energy density and battery performance, and we’ll collaborate with you to choose the most effective solutions for your component’s overall performance.

Work with us to develop high-performance EV solutions. Contact us today to learn more