Battery Applications

Batteries Components Converting

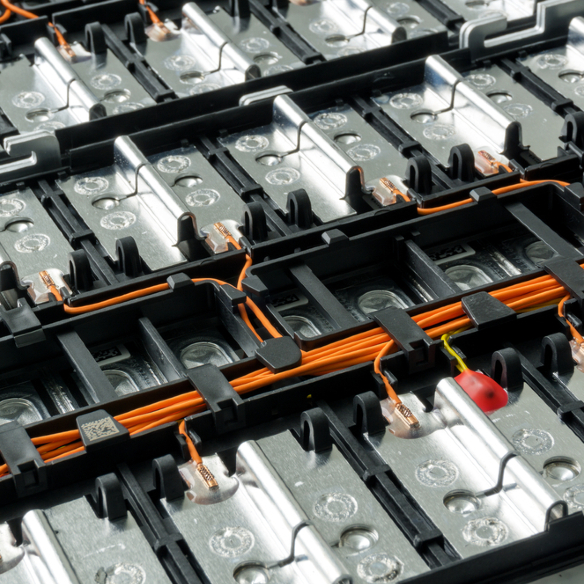

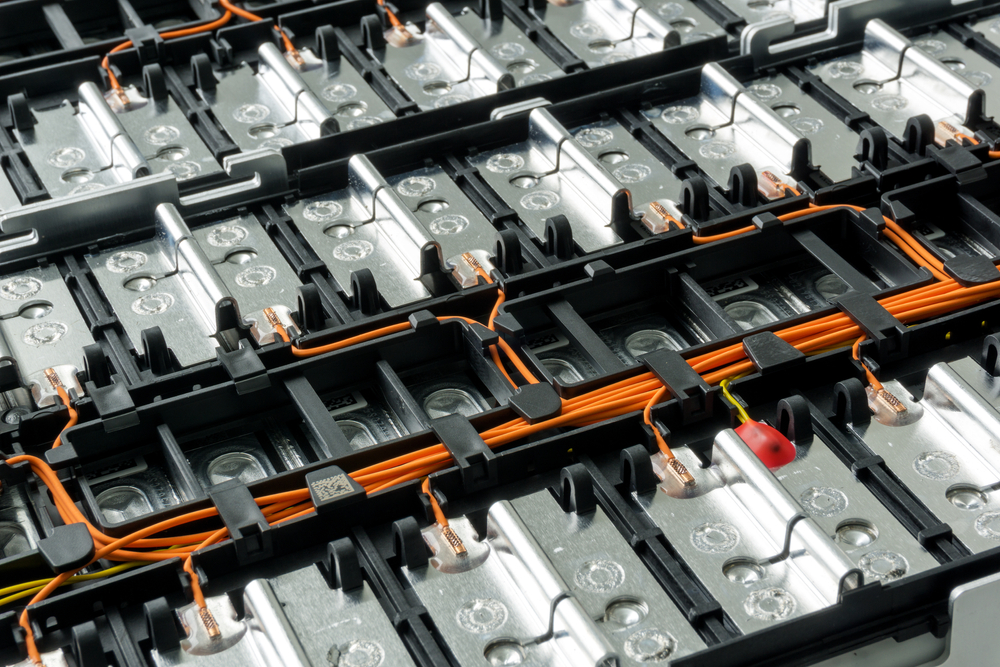

Manufacturers must protect battery electrical components and circuits to ensure safe and efficient product performance, particularly for applications in demanding operating environments. Without proper protection, batteries are vulnerable to excessive moisture, heat, physical stress and other factors that can cause reduced efficiency, safety hazards or product failure. Battery applications requiring specialized solutions range from electric vehicles (EVs) and wearable medical devices to laptops and smartphones.

Advantage Converting offers manufacturing capabilities that maximize battery protection, energy utilization and power density. Our professionals have decades of combined experience helping customers choose the most practical and effective solutions to improve overall product performance.

Battery Protection Manufacturing Solutions

Implementing cutting-edge technologies and strategies enables battery manufacturers to improve product efficiency, longevity and safety to meet consumer needs. Examples of these strategies include:

- Battery sealing: Effective sealing mechanisms prevent moisture, dust and contaminants from entering the battery, helping minimize damage, power drain and safety hazards.

- Battery insulation: Insulation helps maintain stability and prevent short circuits and thermal runaway by creating barriers between different components within the battery.

- EV battery solutions: As the demand for electric vehicles grows, it is crucial to develop high-performance, cost-effective solutions that increase battery durability, storage capacity and charging times.

Converting Services for Battery Applications

At Advantage Converting, we leverage high-quality materials, innovative processes, exceptional design expertise and superior technical knowledge to offer some of the industry’s most innovative solutions in battery manufacturing. Converting services we offer include:

- Die cutting: Die-cutting equipment is essential for producing custom shapes for battery seals, insulation, gaskets and electrode materials.

- Laminating: Laminating equipment creates protective layers and bonds for various battery components, including the electrode materials and separator films that form the battery cell.

- Slitting and rewinding: Precision slitting and rewinding equipment is critical for cutting materials like electrode sheets, separator films and other materials to the required sizes for assembly and packaging.

- Clean room manufacturing: Clean rooms with low levels of dust, airborne particles and contaminants ensure the production of sensitive battery components in a controlled setting.

Types of Materials We Use in Battery Protection Manufacturing

Advantage Converting’s knowledgeable and experienced team can work with you to determine the best-suited manufacturing materials for your unique battery application. Besides being a 3M Preferred Converter, we have longstanding relationships with many of the most recognized material suppliers.

Examples of the types of materials we work with include:

Discover More With Advantage Converting Discover More With Advantage Converting

If you want to learn more about how our design capabilities and innovative processes can help your battery manufacturing operation, the professionals at Advantage Converting can guide you. We can evaluate your production specifications and requirements to recommend solutions that increase battery protection, safety, performance and efficiency. Contact our team online today to learn more.

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: When do I need a clean room?

Clean room manufacturing is primarily used when manufacturing sensitive materials that can be easily contaminated or affected by particles in the air. For example, at Advantage Converting, we have used our clean rooms to manufacture advanced wound care products, solar panel components, and vibration dampeners for the aerospace industry. However, a clean room can be used for any converted good. Our experts can work with you to determine clean room requirements for your project.

Q: What manufacturing processes does Advantage Converting perform in their clean rooms?

We can perform any manufacturing process in our clean rooms, including custom die cutting, laminating, slitting and rewinding, and roll-to-roll manufacturing.

Q: What is clean room manufacturing?

Clean room manufacturing is the use of an enclosed area with strict environmental controls to manufacture sensitive components. The controlled environment – or clean room – limits the presence of dust, airborne microbes, aerosol, and chemical vapors to prevent environmental contamination of sensitive components, such as those for medical, electronic, and aerospace applications.

Advantage Converting has multiple clean rooms that are available for all converted goods. Our clean rooms are certified as ISO 8 / Class 100,000 and ISO 7 / Class 10,000.